Manufacturing Bill of Materials

Bill of Materials (BOM) adding structure to your manufacturing operations

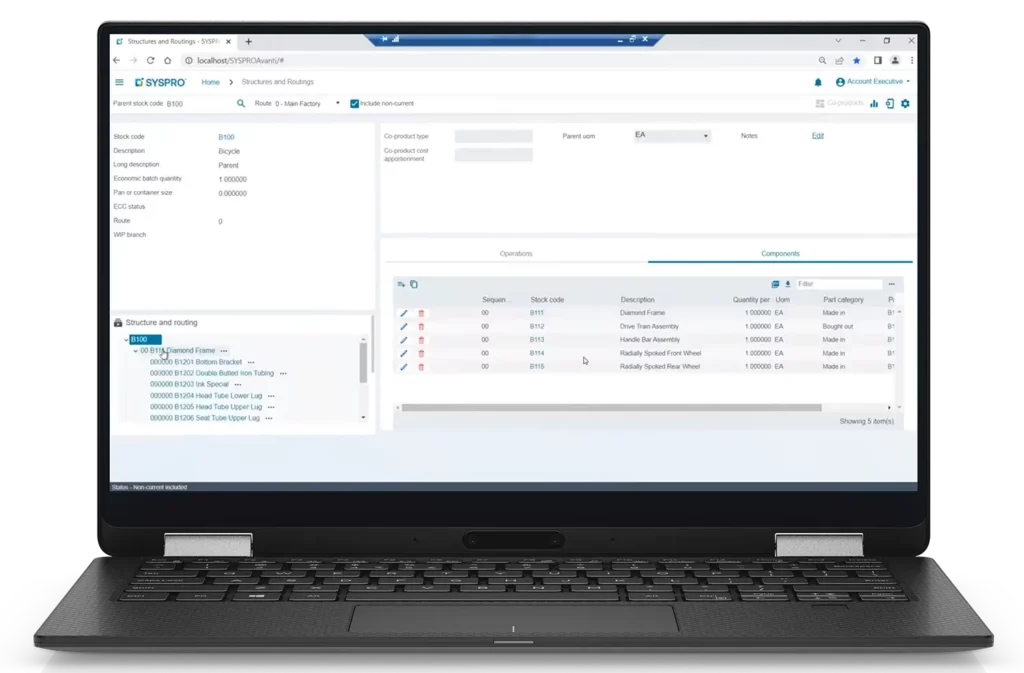

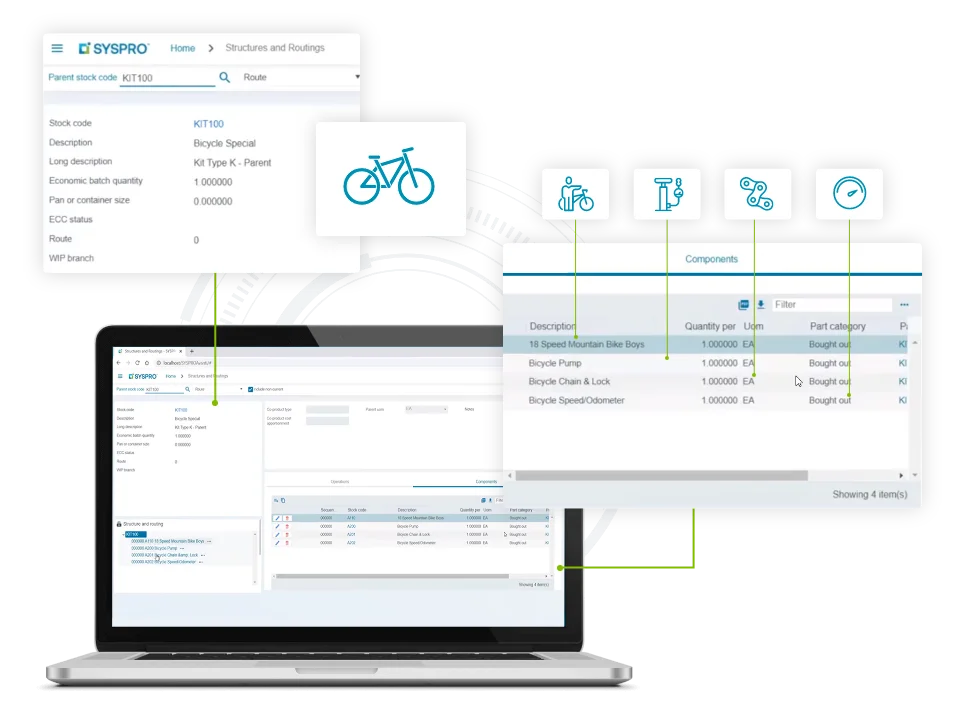

The Bill of Materials (BOM) allows you to facilitate accurate expected costs against which actual production costs can be tracked. The complete bill forms the foundation for material and capacity planning, shop floor control and costing. SYSPRO ERP with Bill of Materials ensures that information is used throughout your manufacturing process, engineering, production, purchasing and order processing.

Manufacturers who require visibility of components and operations that which form part of the end product benefit from BOM as it allows for accurate inventory planning and costing. Using BOM you are able to generate accurate quotes, plan around your operational capacity, produce goods efficiently, and have an holistic view what makes up your end-product/s.

The Bill of Materials is defined by the manufacturing process and it includes:

Operations

|

Components

|

Bill of Materials (BOM) in SYSPRO ERP:

A well-defined BOM helps with the following aspects of the production process:

Planning and purchasing

Material and capacity planning, shop floor control and accurate product costing.

Produce quality goods

Accurate costing

Handle complex manufacturing

Get a first hand view of SYSPRO ERP with BOM to streamline your manufacturing processes

Key elements within SYSPRO's Bill of Materials (BOM)

- Supports up to 15 levels of component sub assembly levels

- Unit, rate and block runtime

- Capacity unit of measure (other than time)

- Capacity measurements and planning

- Material and operation scraps

- Percentage and planning bills, phantom parts, and sub-contract operation

- Optional components for sales of kits

- Co- and by-products

- Import functions for integration to third-party programs such as CAD

Here's what our customers say

SYSPRO’s Bill of Materials (BOM) module has ensured Cibapac’s complete control over their product structures. The complete bill forms the foundation for material and capacity planning, shop floor control, and accurate costing. It’s further ensured that their engineering, production, purchasing and order processing teams are all using the same information. Complex multi-level bill of materials are now able to be costed with the perfect accuracy.

KWAL has benefited from SYSPRO’s ease of use and the ability to monitor costs more effectively. “We now have standard costing practices across the group”, Koskei says. “This has improved the integration of the Rest of Africa businesses into Distell’s head office operation in South Africa. SYSPRO has also significantly improved our productivity. By giving us more active control of our production costs and improved visibility into our operation, SYSPRO is paving the way for us to increase our profits. In addition, SYSPRO has enabled a single repository of data to be built, and this has made monthly reporting and consolidation across the group far easier.”